PLT®

Poultry Litter Treatment

Poultry Litter Treatment

Lower pH and Eliminate Ammonia in Poultry Litter

PLT® is a mineral-based acidifier that lowers litter pH and eliminates ammonia for improved air quality in poultry houses. Top producers rely on PLT for its consistent quality and predictable performance. Pre-placement, mid-flock, short downtimes–only PLT delivers this level of flexibility and safety in application.

PLT Resources

The team at Jones-Hamilton Co. are known as experts on litter management in poultry production. Explore our library of resources to find insights on maximizing product benefits, litter management best practices and more.

Why Choose PLT® - Poultry Litter Treatment

The first (and safest) litter amendment

PLT poultry litter treatment (sodium bisulfate) has been made in the U.S.A. since 1994 and continues to be the leading litter amendment due to its reliability, efficacy and value. It is the only non-hazardous (per current US DOT guidelines) litter treatment on the EPA Safer Choice Program Safer Chemical Ingredient List.

PLT can be used in poultry houses of every type, regardless of program (conventional, NAE, etc), and can be applied anytime – even with birds in the house.

Eliminate Ammonia and Lower Litter pH to Improve Bird Performance

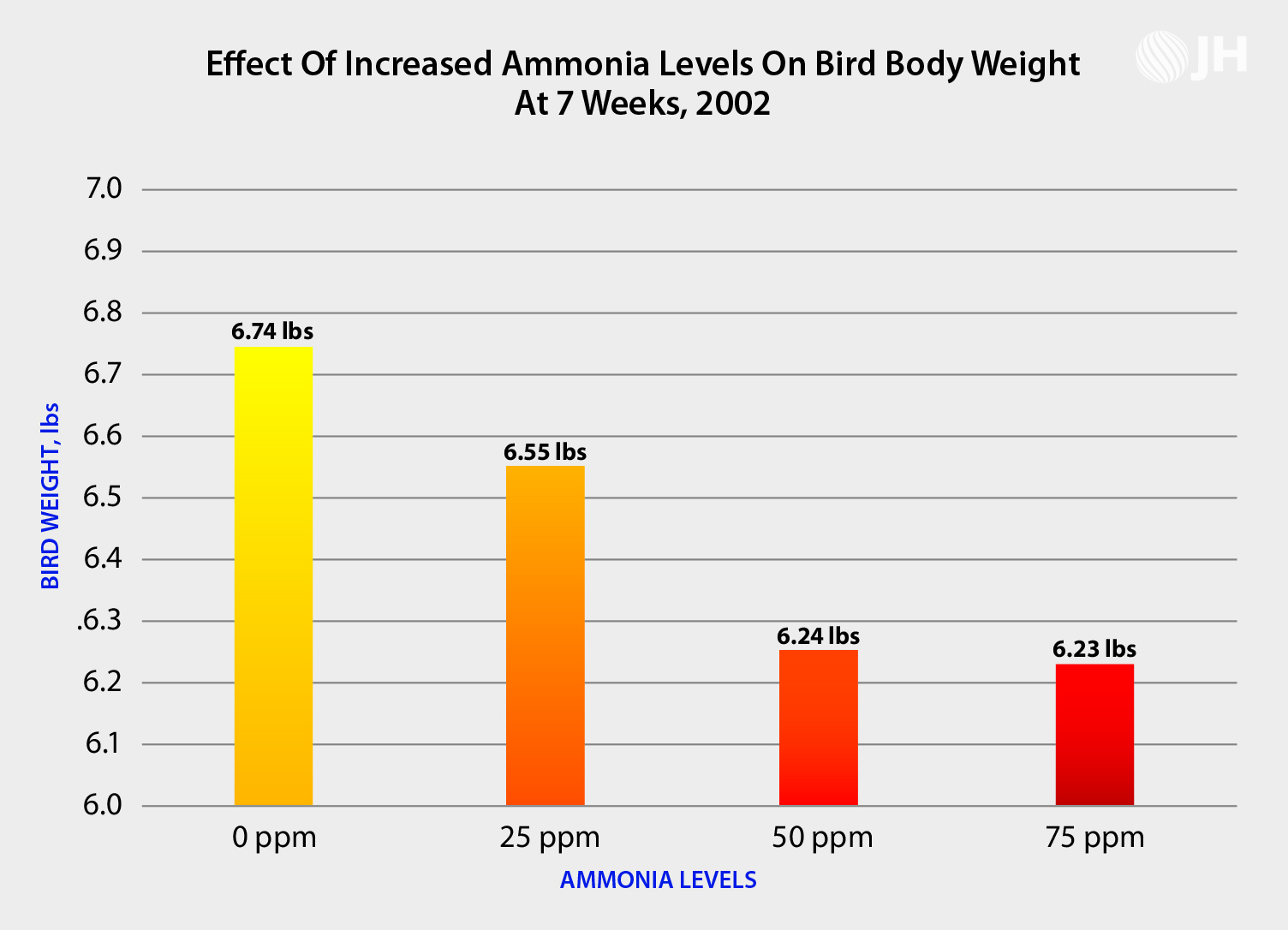

Ammonia can have severe detrimental effects on poultry feed conversion and body weight gain. Decades of research have shown that exposing birds to 50 ppm of ammonia (NH3) can reduce FCR by as much as 10 points.

At 7 weeks, ammonia’s impact is clearly evident on bird weight. Even ammonia levels under 25 ppm can significantly reduce profits.

Impact of Ammonia on Body Weight at 7 Weeks

Low pH = Favorable Environment for Birds

The target pH for poultry litter is 4.0 or below because at that level odor-causing bacteria are suppressed. Higher PLT rates keep the pH lower for longer.

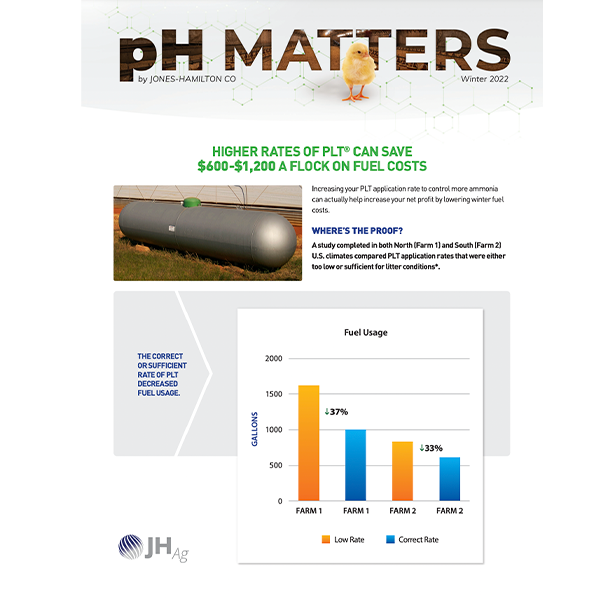

PLT Helps Growers Save Money on Fuel

PLT reduces fuel costs by allowing houses to be ventilated based on relative humidity rather than over-ventilating to remove ammonia. When PLT is applied at a rate that is sufficient for the ammonia challenge, fuel use has been shown to decrease by 33-37%.

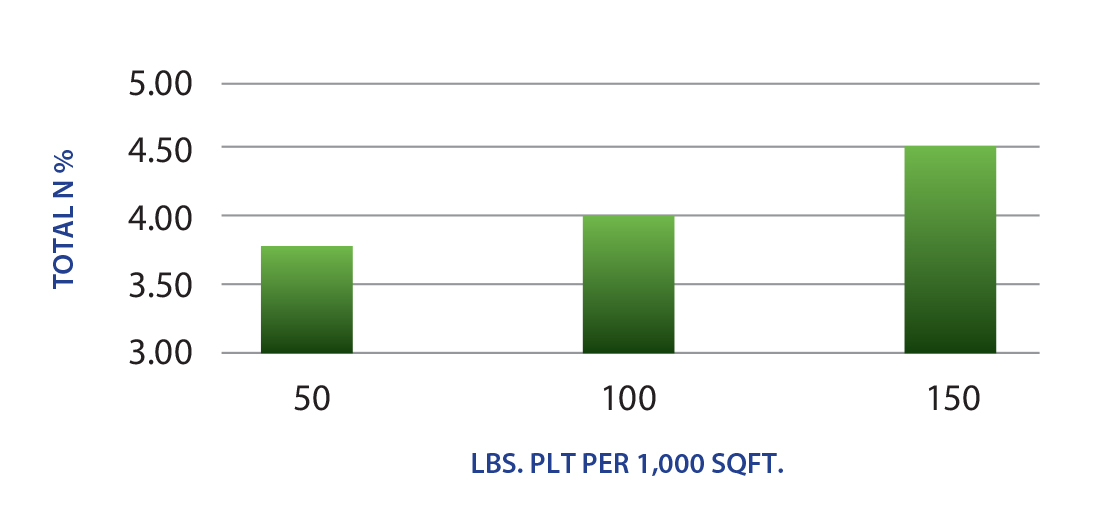

Increase Litter’s Value as a Fertilizer Source

55 lbs. of ammonium sulfate fertilizer is generated for every 100 lbs. of PLT that is applied. As PLT retains nitrogen and turns ammonia gas into fertilizer, the value of the litter increases substantially.

Amount of retained Total Nitrogen in litter after PLT usage over three flocks

Amount of NH4-N in litter after PLT use over three flocks

PLT Frequently Asked Questions

Rate & Application

How do I decide what rate of PLT to use?

The general guidelines on the PLT Product Data Sheet recommends the following:

- Broiler litter: 1 year old or less – 75-100-lbs. / 1,000 sq. ft. of floor space

- Broiler litter: Older than 1 year – 100-150-lbs. / 1,000 sq. ft. of floor space

- Windrowed litter – 150+ lbs. / 1,000 sq. ft. of floor space

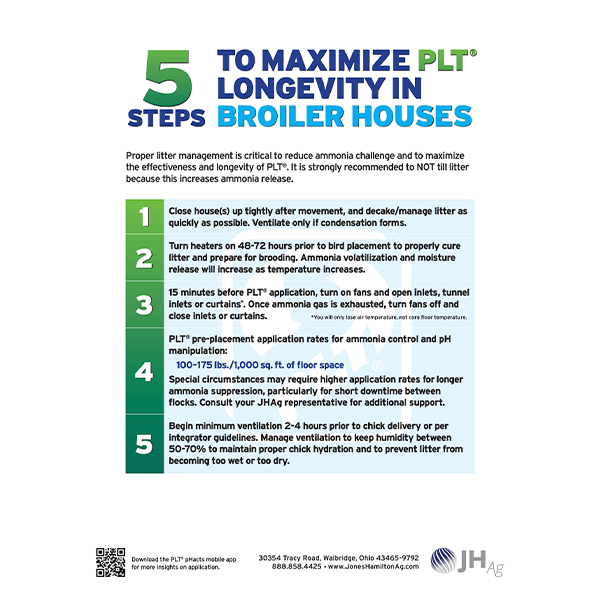

PLT may be applied prior to pre-heating or up to day of placement. NOTE: if applied prior to pre-heat, early activation of the project may result in reduced product longevity. Therefore, an application rate of 150-200 lbs./1,000 sq. ft. is recommended.

How does PLT affect the litter pH?

When can I apply PLT?

Has the recommended timing of PLT application changed?

PLT and most litter amendments are hygroscopic, meaning they start to activate immediately upon application. When PLT is applied prior to set up or pre-heating, the product will not last as long into growout. Instead it will activate with the large amount of ammonia that comes off the floor during pre-heating and leave less product available to control ammonia once birds are placed.

If applied prior to pre-heat, early activation of the project may result in reduced product longevity. Therefore, an application rate of 150-200 lbs./1,000 sq. ft. is recommended. Application timing will affect the longevity and recommended application rate for ALL litter amendments.

I don’t smell much ammonia. Can I cut my PLT rate?

Why should I turn on fans and drop curtains before application?

Does PLT® need heat to activate?

No, PLT does not require heat to activate and can be applied on a cold floor. Just like all litter amendments, the product will start reacting with ammonia as soon as it is applied. If PLT is applied before floor temperature reaches 85 degrees, the product will be consumed by the ammonia purge leaving very little to control ammonia during the rest of the brooding period. PLT is hygroscopic and does require moisture to activate.

How long will PLT last?

Should I use PLT in the off chamber?

Safety

Is PLT hazardous?

Is it safe if PLT gets in the feed?

Is it safe to apply PLT with birds in the house?

Is PLT corrosive?

Basic Troubleshooting

What does the “PLT Cloud” mean?

I have wet spots on my chick paper. What does that mean?

I applied PLT as directed, but I still had ammonia when my birds arrived. What happened?

Economics

How does using PLT save fuel?

How does PLT increase my fertilizer value?

Moisture, Litter Management and PLT

What happens to ammonia when litter is heated?

How does relative humidity impact PLT?

On the other hand, if the RH % is above 70%, the opposite will happen. The extra moisture will cause the PLT to activate too quickly, decreasing the longevity of ammonia control.

How does PLT impact paw quality?

Should I spray the litter with water if it is too dry?

What should I maintain as my minimum litter depth?

How do moisture levels in litter affect house management?

How long can I reuse my litter?

Never Miss the Latest Research

Subscribe to get the latest news and litter management tips.