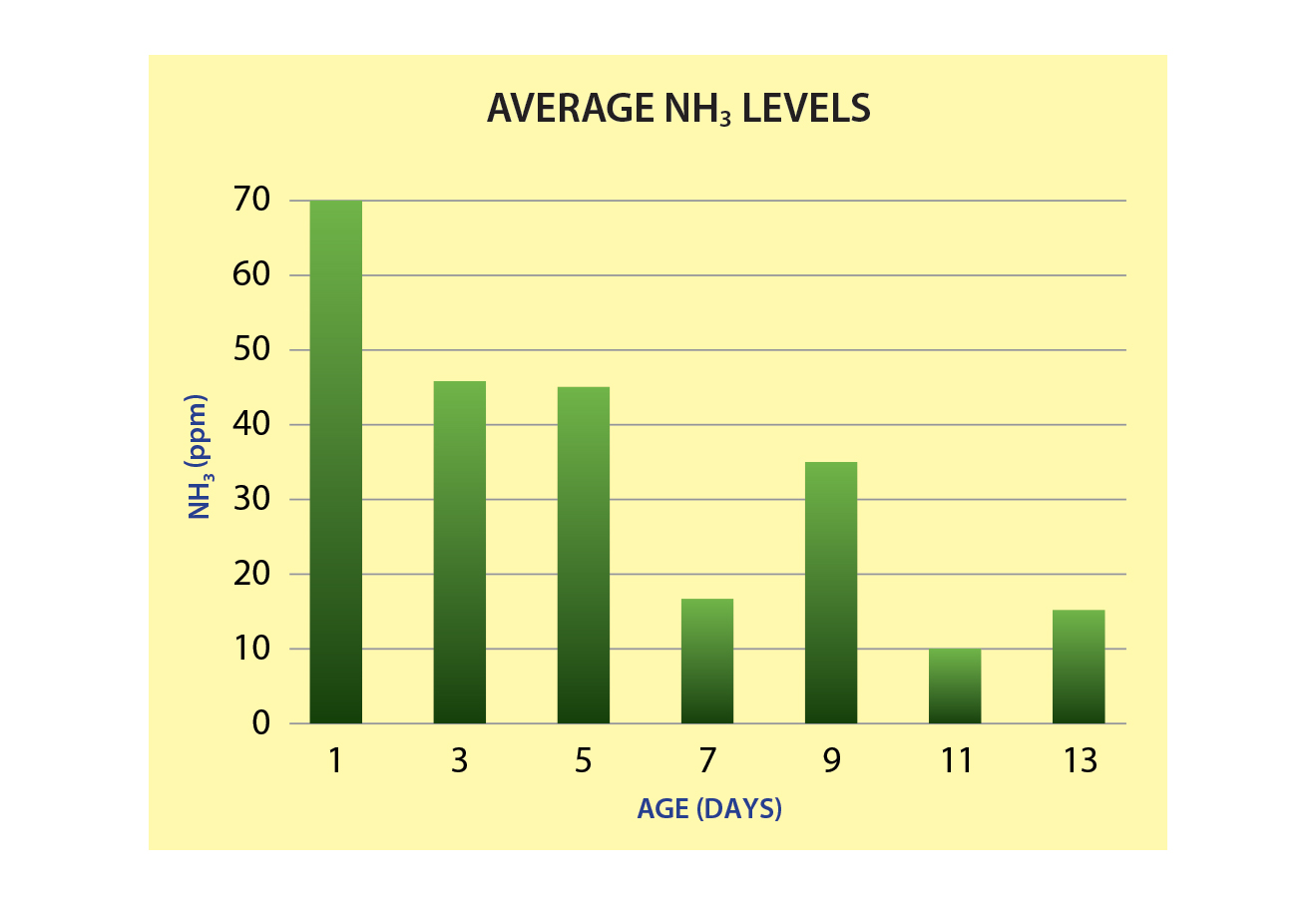

The idea that ammonia isn’t an issue in poultry houses in the summer is a pretty common one, which is perhaps why data has shown that ammonia levels in the 48 hours following chick placement tend to top 50 PPM – levels high enough to reduce body weight and feed efficiency, and harm bird eyes and respiratory systems.

The idea that ammonia isn’t an issue in poultry houses in the summer is a pretty common one, which is perhaps why data has shown that ammonia levels in the 48 hours following chick placement tend to top 50 PPM – levels high enough to reduce body weight and feed efficiency, and harm bird eyes and respiratory systems.

Need litter management expertise?

You've found it.

Even during the hottest days of summer, full ventilation is not maintained 24/7 on chicks. As ammonia is released from the litter, ventilation programs cannot sufficiently remove it all.

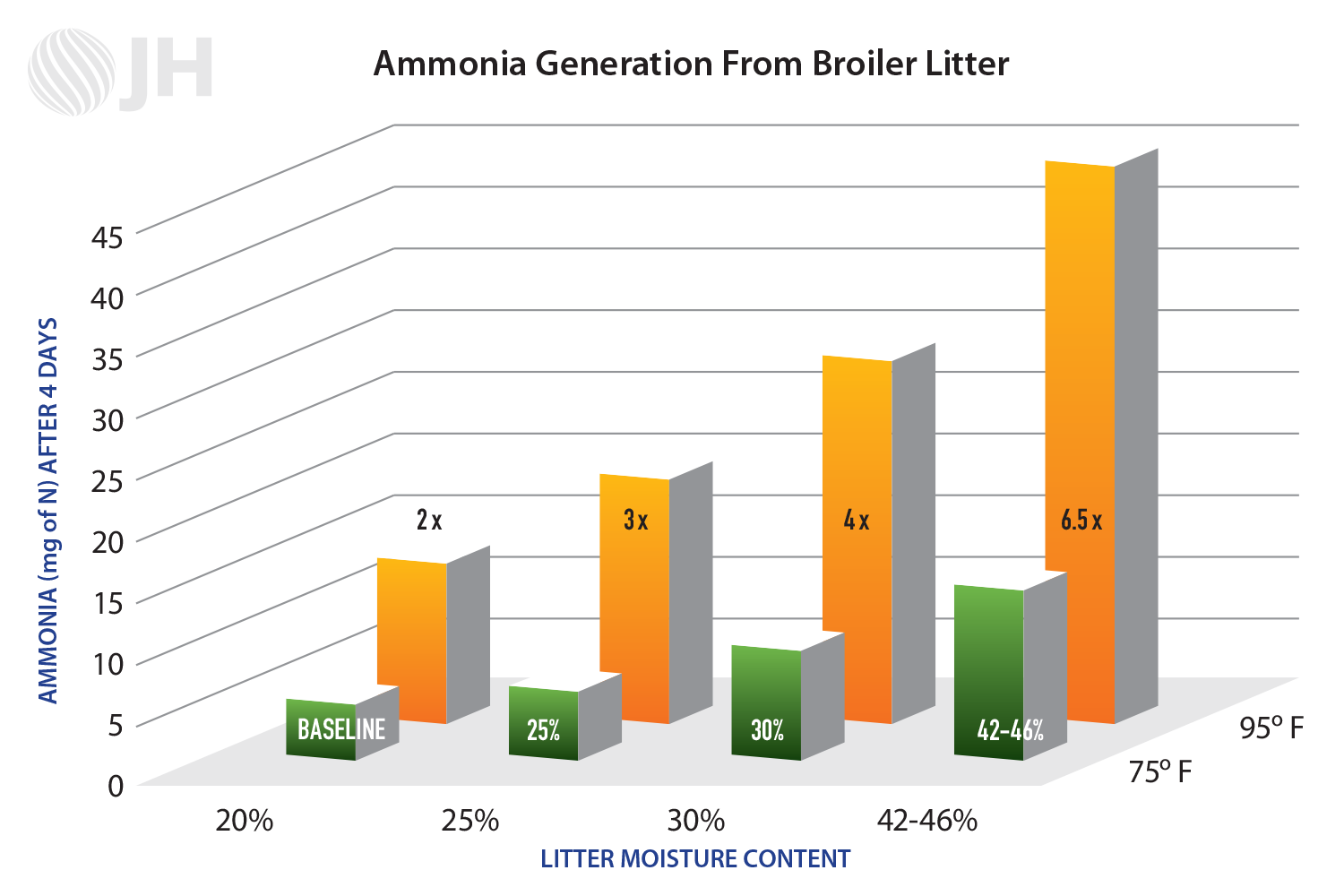

In addition, moisture, which is introduced from birds, waterlines, humid outside air, evaporative cooling systems and other sources, can easily build up during summer despite increased ventilation. Moisture is the top variable that impacts ammonia production.

Even slight increases in litter moisture can cause substantial increases in ammonia volatility—and that impact is magnified as temperatures rise (Figure 2).

The Added Insult of Moisture on Ammonia and Paw Lesions

In addition, moisture, which is introduced from birds, waterlines, humid outside air, evaporative cooling systems and other sources, can easily build up during summer despite increased ventilation. Moisture is the top variable that impacts ammonia production.

Even slight increases in litter moisture can cause substantial increases in ammonia volatility—and that impact is magnified as temperatures rise (Figure 2).

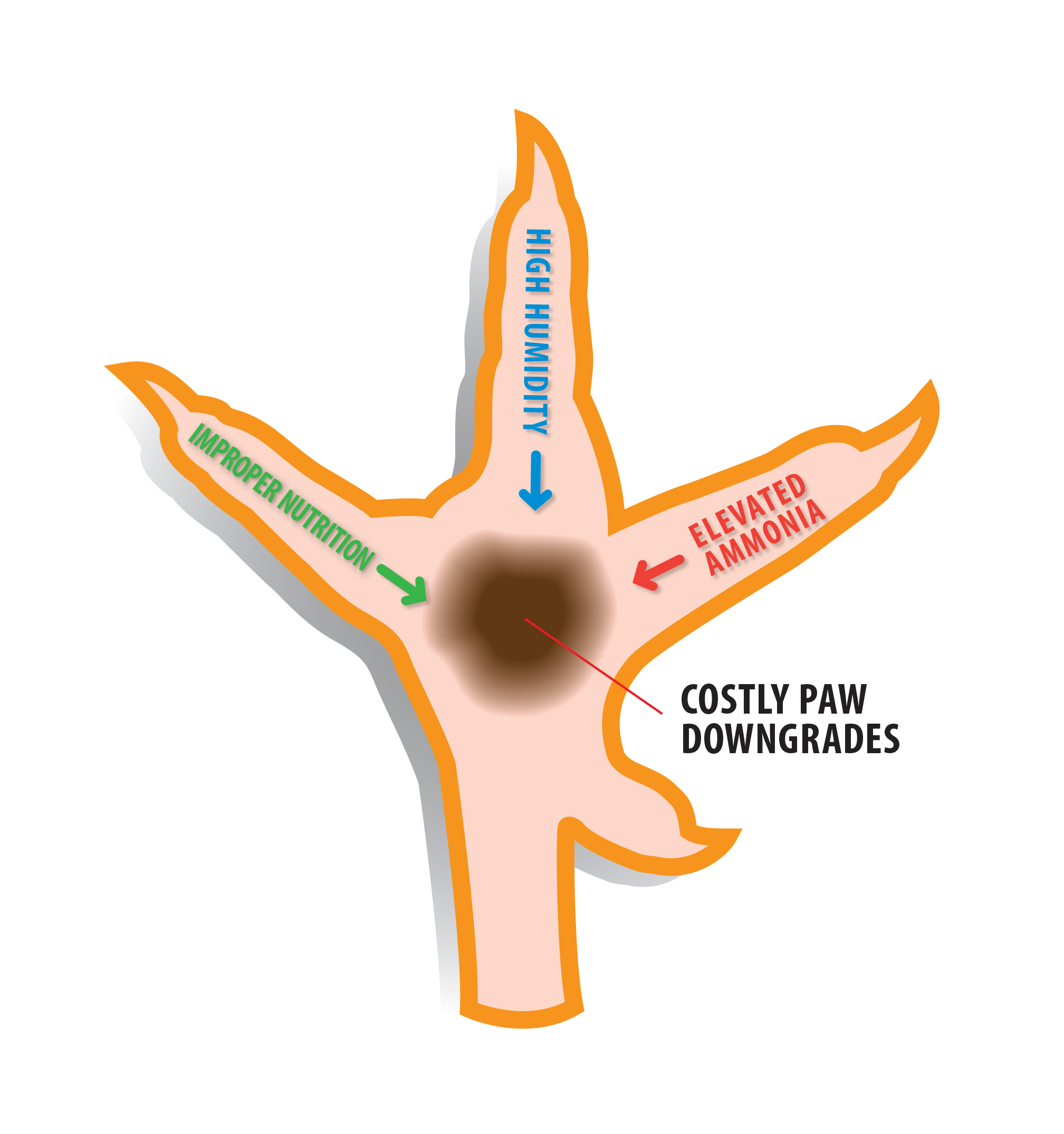

Litter moisture is also a top contributing factor for the development of paw lesions, a profit center for poultry companies. If litter moisture is too high and litter sticks to the feet of birds, it can begin to erode the skin and cause lesions.

Given that only Grade A paws can be sold and the value of paw exports is roughly six times what it was eight years ago, all of which goes to the bottom line, keeping moisture down and paws healthy is beneficial to the bottom line.

Short Downtimes and the Moisture Challenge

For complexes facing extremely short downtimes of just three to five days, this can be difficult. Moisture removal is a key focus during downtime and without enough time to accomplish this task, houses can remain wet. The result? The next flock will be potentially challenged with wet litter which means high ammonia and bacteria levels, and issues with paw lesions.

With sufficient downtime, decaking and fans can work to dry litter. However, heaters are the fastest way to dry litter and are therefore necessary during short downtimes. Heating houses to 100°F or more has the potential to reduce litter moisture. Combined with minimum ventilation, a temperature of 100°F for approximately three days could potentially reduce litter moisture from 35% down to 15%.

Ventilation alone is often not sufficient to manage ammonia levels and moisture in summer. PLT, the amendment growers commonly use in winter to control ammonia, is also the best way to control it during summer months for improved bird performance and welfare. PLT neutralizes ammonia that is in solution, which also works to preventing paw damage.

If you’re losing revenue from damaged paws, talk to a Jones-Hamilton Co. representative about ideal PLT application rates in summer.